The steam generation cost using our CSP technology is significantly lower compared to Coal and other fossil fuels.

Sunrise CSP’s core technology is the Big Dish which is a high-performance solar energy concentrator. Sunrise CSP’s Big Dish is a 3rd generation technology that has benefited from over 40 years of research & development commencing at the Australian National University (ANU) in the 1970s.

Sunrise CSP owns the patents for the Big Dish structure, the Mirror Panels and the SUMO Molten Salt Thermal Energy Storage charging system. We are the exclusive global licensee of the ANU’s Super-heated Steam Receiver, the world’s highest efficiency solar boiler.

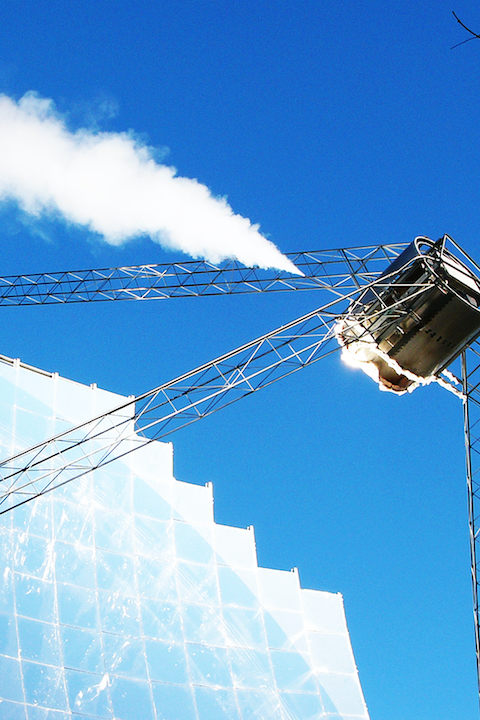

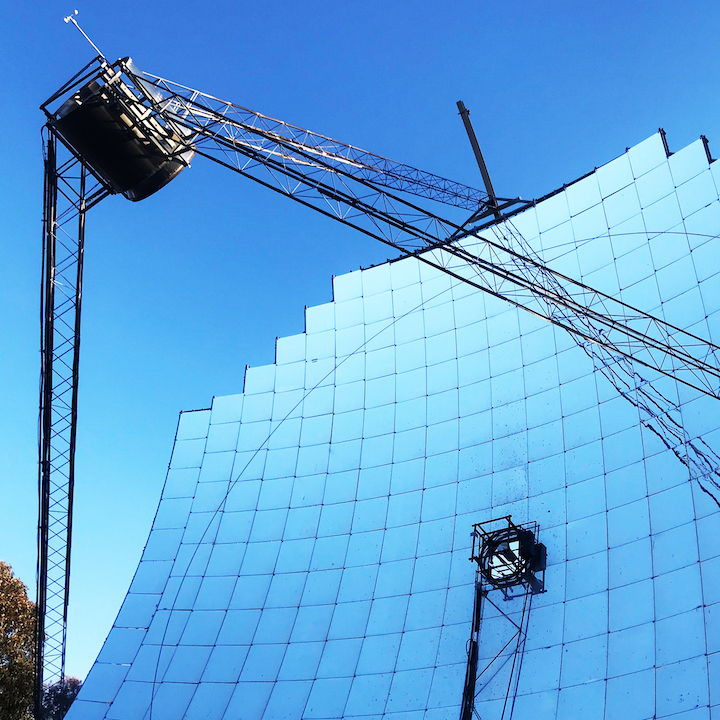

The Big Dish is the world’s largest solar concentrating dish with a 500m2 surface area that delivers highly concentrated solar energy (>2000 suns) to a receiver. This energy is then used to make steam in the Receiver at temperatures and pressures ranging from 100oC to 600oC and 1bar to 160bar depending on the application. This steam can be used for process heating or cooling or electricity generation.

- Superior Optical Efficiency

High optical efficiency is achieved by having the full face of the dish tracking the sun at all times. Dual-axis tracking ensures that the Big Dish does not suffer any cosine losses, unlike tower/heliostat, trough and Fresnel concentrator systems. Combined with our high-performance mirror panels, with less than 1.5 mrad slope error and >94% reflectivity, our dishes deliver superior optical efficiency, typically about 90%. - High-Temperature Operation

The Big Dishes high concentration ratio (>2,000 suns) creates thermal energy at temperatures approaching 2,000oC. Today, this high-temperature thermal energy is used to create steam at 100oC to 600oC. The next generation of Receiver technologies will deliver high temperature thermochemistry to produce hydrogen, ammonia and other fuels and chemicals, and support high-temperature processes like sintering of metals, ceramics, plastics and other materials. - Superior Thermal Efficiency

The high concentration ratio of the Big Dish (>2000 suns) means a much lower receiver area subject to thermal losses by radiation and convection. Testing by the Australian National University has demonstrated Receiver thermal efficiencies of 97%, the same as a state-of-the-art fossil-fuel steam boiler system. When combined with high-optical efficiency this means the overall solar-to-thermal efficiency of a Big Dish is approximately 87%. - Modular & Scalable

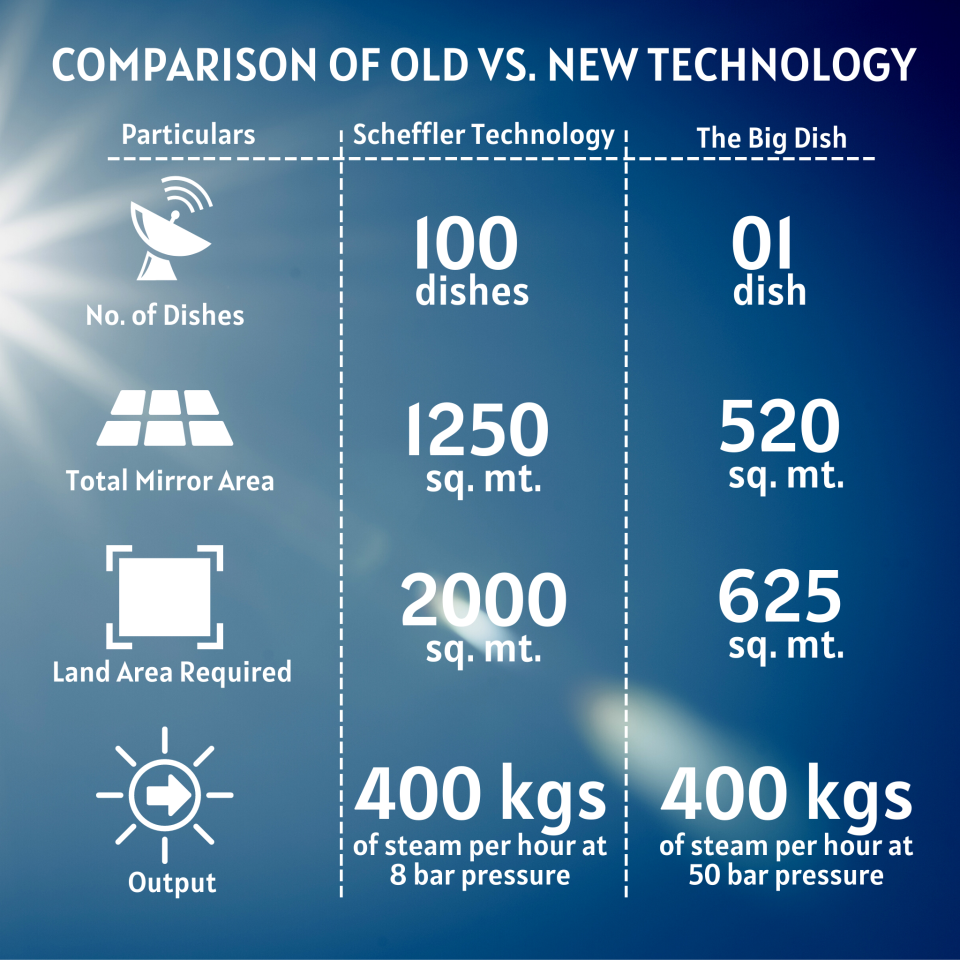

One Big Dish delivers 436 kW thermal power (@ 950W DNI) with a land-use footprint of just 625 m2. Big Dish plants can be as small as 1 dish to many hundreds of dishes connected by a steam pipe network. Energy losses in the network are negligible due to low-cost piping insulation. Large plants can be built and commissioned in stages to realise the benefits from each stage as early possible, with progressive expansion that aligns with expanding demand for energy or investment milestones. - Low Cost Per Unit of Energy

The 500m2 dish size and efficiency dramatically reduces the solar field fixed costs (motors, control systems, receivers, etc) and land area needed. Additionally, a light weight, low-cost and highly accurate space frame structure that is rapidly assembled combined with mirror panels designed for mass manufacture / installation bring down the installation cost.

Efficiency of manufacture, installation, operation and solar-to-thermal conversion = a low cost per unit of energy delivered.

Sunrise CSP also offers Scheffler Dishes for smaller process heat plants and as a low-cost entry point to solar thermal solutions. With a 16 m2 mirrored surface, Scheffler Dishes are a modular and scalable system that grows in 5kW-thermal units and is ideal for applications that need as little as 5kW-thermal up to 300kW-thermal. The lightweight of Scheffler Dishes means they can be mounted on flat roof tops and terraces. Typical applications include community & institutional: cooking, thermal water desalination, space heating / cooling and refrigeration.

For applications needing more than 300-kW thermal then we recommend the Big Dish to reduce the system footprint, O&M costs and increase efficiency, thereby significantly lowering the cost of energy delivered for larger applications

* the higher-pressure Big Dish steam is used to charge a pressurized hot water storage system that can deliver multiple streams of steam on-demand. The steam from storage will be used for laundry operations, sterilization, space cooling and cooking at MSA. These applications need steam ranging from 100oC to 200oC at 8 to 18 bar, depending on the application.

Solar Mirror Panels (SMPs) are used to reflect sunlight onto the Receiver.

If the Big Dish forms the core of Sunrise CSP’s technology, then SMPs are the essence.

The accuracy and efficient design-for- mass-manufacture & installation delivers a low-cost optical system that supports a rapid and cost-efficient solar field deployment.

Sunrise CSP owns the patents for SMPs.

- Focal Accuracy

Each panel is formed accurately with less than 1.5 mRad slope error. This means that every ray of sunshine captured is accurately delivered to the Receiver. - Highly Reflective

The panels utilize the world-leading, low iron, thin (1mm) mirrored glass with over 94% reflectivity to deliver the maximum possible solar energy to the receiver. - Quality Control and Product Traceability

Every SMP is tested using advanced photogrammetry measurement systems and is uniquely identified with a code. This code provides a lifetime link between field performance and the materials and production parameters of each SMP. - Low Unit Cost

Designed for high volume automated production and installation, every SMP is the same size, shape, focal specification and material composition, delivering a low unit cost. - Optimized for Installation and O&M

SMPs are installed directly onto the dish structure with no focal adjustment required at installation or throughout the life of the plant. - Structural Strength

SMPs are a composite structure and a structural element, not a dead weight, so that each mirror panel contributes to the dish stiffness and reduces structural steel costs. - Low O & M

SMPs are robust and durable with a target life of 30 years. They are designed to withstand harsh environmental conditions caused by wind, dust, rain and hail. The Big Dish reflective surface is designed to support both automated and manual cleaning systems – strong enough to have a maintenance crew walk on them. - Total CSP Market Solution

The focal length of SMPs is tuneable for a variety of CSP systems, through concentrators and heliostats, opening up opportunities for it to be used in alternative CSP systems.

The Receiver, developed by the Australian National University (ANU), collects the highly concentrated solar energy of more than 2000 suns. The high average concentration ratio of the Big Dish (>2000 suns) means a much lower receiver area subject to thermal losses by radiation and convection. The end result is a boiler system delivering >96% efficiency of converting solar radiation to thermal energy.

Sunrise CSP has the exclusive global rights to the ANU’s Receiver technology.

Sunrise CSP brings a portfolio of solar thermal energy storage technologies to enable on-demand, time-shifted and time-extended thermal energy delivery for dispatchable process heat and electricity generation solutions.

- Pressurised Hot Water

- Thermal Oil Storage

- SUperheated steam – MOlten salt (SUMO)

- Thermochemical, eg. Metal Hydride, Storage

Sunrise CSP offers Pressurised Hot Water storage solutions for process heat applications needing temperatures up to 400oC, e.g. space heating/cooling, institutional cooking & laundry, hot water supply, sterilization, food/diary processing, refrigeration.

These storage systems use the high-temperature output of Big Dishes, typically at 500oC, to efficiently charge the storage. When steam is required then steam is generated from storage using a flash tank or heat exchanger.

The system can also be used for producing hot air using a steam-to-air heat exchanger.

Sunrise CSP is developing a thermal oil Receiver-Storage-Steam generation system that will heat thermal oil directly in the Receiver and store that oil in a tank at up to 450oC. When steam or hot air is required then it is generated from storage using an oil-to-steam / air heat exchanger.

The advantage of this system the ability to heat and store oil at atmospheric pressure and does fall under pressure vessel and boiler codes.

Sunrise CSP has developed a unique approach to molten salt energy storage that is ideally suited to the high steam temperatures that the Big Dish achieves. SUMO is specifically designed to support the requirement for dispatchable electricity generation using state-of-the-art steam turbines with capacities of tens to hundreds of megawatts.

SUMO allows high-temperature energy transportation from a Big Dish solar field to an industry-standard molten salt thermal storage system allowing molten salt temperatures up-to 600oC, with higher temperatures to be available in the future as salt media develops.

Sunrise CSP owns the patent for the SUMO superheated steam transport process.

Sunrise CSP has partnered with a German company for the integration of Metal Hydride storage where hydrogen is used as a heat carrier.

The technology is proven at pilot scale and Sunrise CSP is collaborating on scaling up to commercial scale using our Big Dish.

The Factory-in-the-Field (FiF) is a purpose-built, scalable and relocatable facility for high volume, high quality, manufacturing of Big Dishes on the power plant site. It includes automated quality assurance ensuring a globally consistent, high-quality approach to solar field deployment. It reduces the solar field deployment costs, accelerates project development, and maximizes opportunities for local employment and suppliers.

- Cost-Effective Option

The FiF delivers rapid and cost-effective solar field deployment. Materials (like steel pipe, steel coil) and “kits” (like fasteners, dish motors, electrical and control systems) are delivered to the site. Dishes manufactured on-site using structural materials are transported by weight and not volume, significantly reducing transport costs. - Adaptable to Regional Circumstances

The FiF includes operational options for automation, labor content, equipment and materials sourcing, which are adaptable to suit regional circumstances, facilitating local supply and manufacturing. - Large Production Module

FiF production modules are modular and designed for scalability. The FiF ensures that multiple Big Dish solar power projects can be under construction in many locations around the world simultaneously.The Small-Field FiF module is designed to deliver up to 100 dishes per year by adding the core component of an FiF – the Big Dish Jig.Similarly, the Large-Field FiF Module can be scaled from 300 to over 1,000 dishes a year by adding more FiF modules.With each dish delivering an average of 400kW thermal then this represents scalability of delivery from 40MW-thermal to over 4GW-thermal per year per FiF system. - Efficient Manufacturing and Assembling

Materials are processed just in time using Special Purpose Machines (SPM), minimizing materials handling and warehousing. Low-tolerance parts are assembled on high-tolerance jigs, resulting in a precision structure, rapidly built from inexpensive on-site fabricated structural components. - Global Quality Consistency

Integrated and automated quality assurance is achieved by using advanced laser measurement and photogrammetry ensures a globally consistent high-quality approach to solar field manufacture and deployment. - Promotes Community and Government Support

Flexibility in manufacturing, labor, materials and equipment supply, maximizes local content and promotes community and Government support. In India the FiF is delivering over 90% local content for the solar field.