Concentrating Solar Power (CSP) Research commenced at the Australian National University at Canberra, Australia.

- The world’s most efficient and largest paraboloidal dish solar concentrator – The Big Dish

- High optical performance Laminated SMP

- On-demand and time-extended energy delivery – SUMO

- World’s highest efficiency solar-steam receiver

- Factory-in-the-Field system for maximizing local manufacturing and supply opportunities

ANU commenced work on Australia’s 1st Solar Power Plant in White Cliffs, New South Wales. The plant used 14 parabolic 1st generation dishes having an area of 20 square meters. With direct steam generation (DSG), connected to a 25 kW steam engine and a battery system, dispatchable electricity was provided to the remote town. The plant operated for 1094 days between the period 1983-1989. High-temperature DSG from a distributed dish field was successfully demonstrated, and a good deal of experience was gained for new system components and its operations resulting in valuable lessons on economies linked to the size of dishes.

ANU completed construction of the 2nd generation big dish technology, the 400 Square Meter SG3 System. Using a steam receiver, SG3 was connected to a steam engine/generator, which was in turn connected to the grid. The system demonstrated the viability of significant LCOE reductions if used in plants of sufficient scale, tens to hundreds of megawatts. SG3 demonstrated the high-temperature capability of dishes, generating temperatures in excess of 1400oC. Operational until 2012, SG3 was the world’s largest CSP dish by a factor of almost three.

Sunrise CSP patented a method for constructing the space frame of the Big Dish. The structure is formed on a jig from curved metal beams, with a rear structure of pyramids and cords and a front surface of reflective panels. A key element of the patent is the use of long curved beams that conform, upon installation on the jig, to the parabolic shape of the dish.

- Sunrise CSP acquired patents for solar mirror panels, the method of their manufacture and also the SUMO Technology.

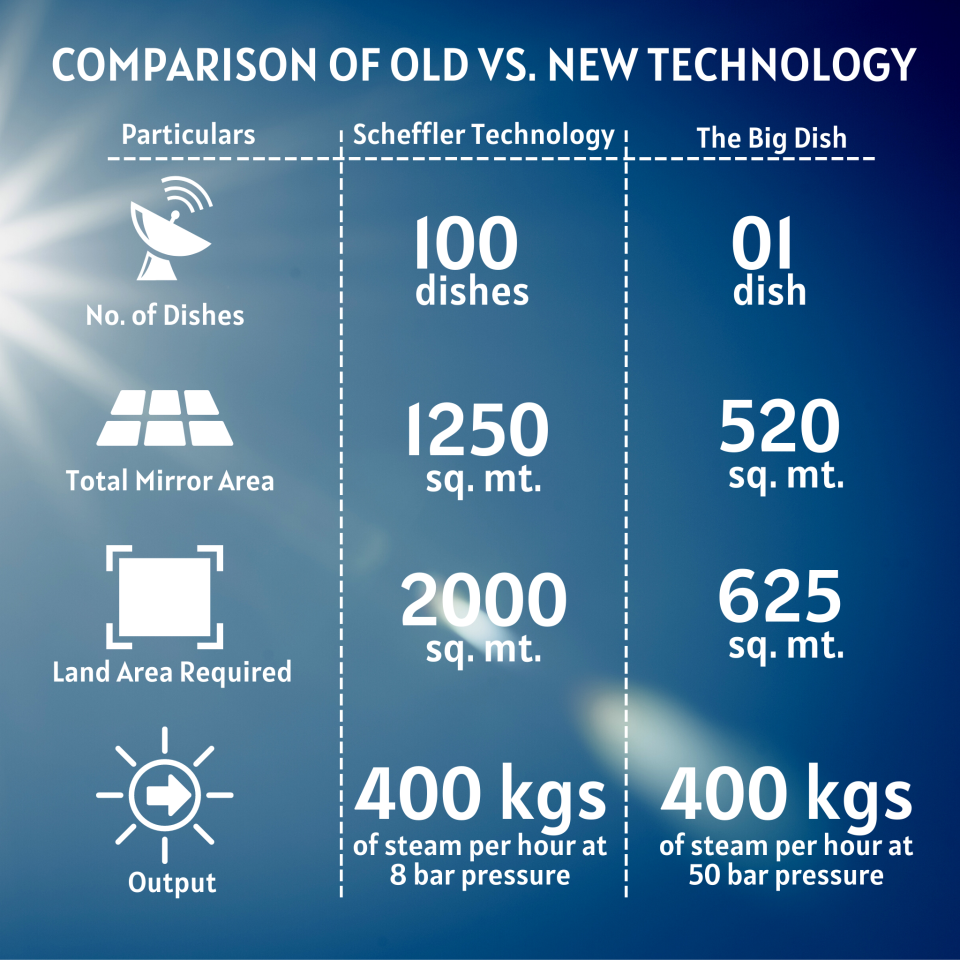

- Completion of construction and testing of the 520 square meter 3rd generation commercial big dish, at the ANU.

- The Factory-in-the-Field (FiF) system for on-site manufacturing was developed with mission-critical FiF sub-systems

- Applications for Patents had been filed for Novel space frame and mirror panel designs.

Licensed World’s High-Performance Super-Heated Steam Receiver From ANU

Establishment Of Sunrise CSP India Pvt Ltd in India

- Establishment of Sunrise CSP International Ltd in Cyprus

- Installation of manufacturing unit of Solar Mirror Panel at Muni Seva Ashram (MSA), Vododara, India.

- Commencement Of first Big Dish (SG4) plant at MSA, India

Solar Cells, also called Photo Voltaic Cells converts the sunlight directly into Power/ Electricity whereas Solar Concentrator generates heat in form of hot water, hot air and steam and thermic fluid. These, in turn, can be used in applications ranging from Grid-Scale Electricity Generation to providing heat for industrial processes. Steam at a high temperature can also be used to generate power by running turbines.

The efficiency of Sunlight to Power Generation in PV is approx. 18%

The efficiency of Sunlight to Power Conversion if generated using a Steam turbine can be between 24-40 %. Importantly the cost of storing thermal energy in a Concentrator Dish is significantly lower than PV battery storage.

Both technologies are complementary to each other and have their pros and cons.

Solar cells are mostly fix and forget type systems and just need cleaning for maintenance. They have no moving parts, work in diffused sunlight and are scalable. However, they have poor efficiency for power conversion.

This is where Concentrator Dish technology comes into play.

Concentrator Dishes are far more efficient for power conversion. CSP can provide the heat needed in industrial processes. Through Big Dishes and low cost thermal storage, CSP technology manages the peaks and troughs of intermittent power generation.

CSP technology delivers lower-cost heat compared to other technologies and natural resources. The ROI delivered by the technology is far superior. (Click here to know more)

The Big Dish SG 4 has three deliverables and sometimes it can be only one in form of electricity when used for power generation only or it can be both power generation and industrial energy solutions (high-temperature processes).

Thus, the technology can be applied to a multitude of industries. (Click here to know more)

O&M is very low. It only requires mirror cleaning and lubrication of moving parts.

The engineering design life of a plant is of 30 years. However, well-maintained plants will last many more decades.

And considering our solar system, the technology can operate approx. 7 hours a day and for about 300 days annually.